Innovation

Réinventons-le-câble-de-demain

Cable is one of those products that you handle every day.

Because of the strict standards they have to meet on the French market, the possibilities for developing cables are still relatively limited.

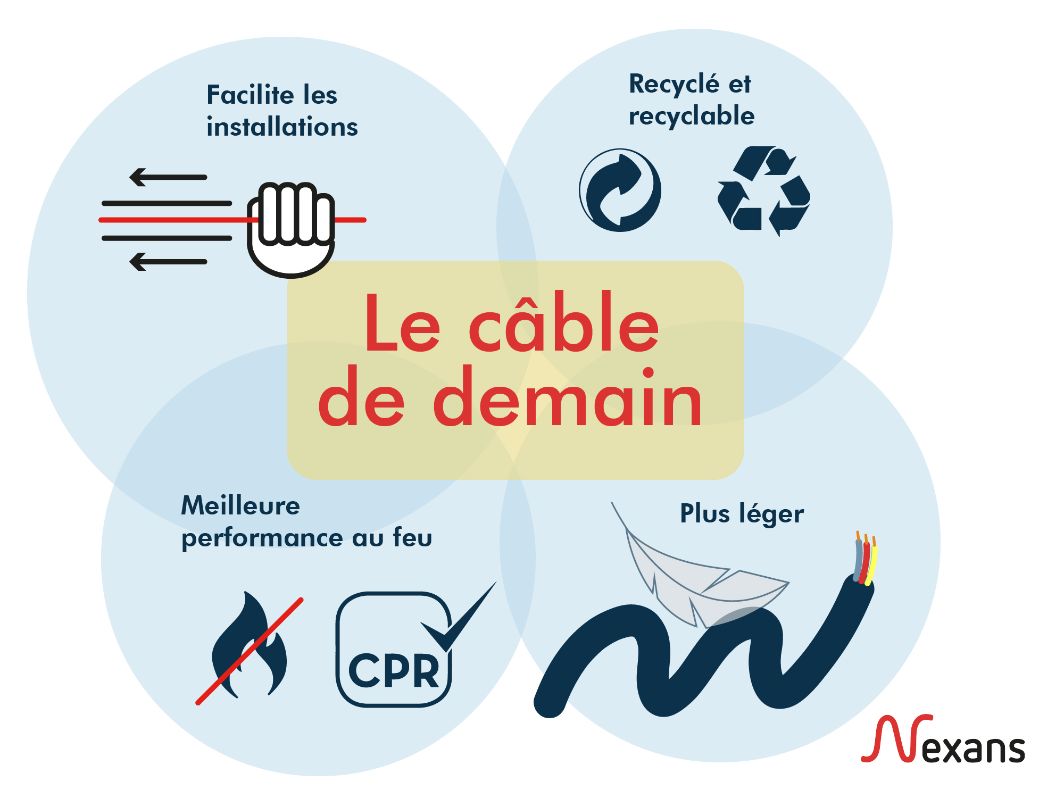

However, these days, a cable can't just be functional; it has to provide you with a concrete solution and save you time. That's why Nexans came up with Distingo NX'TAG. This solution reinvents the way you install cable on your worksites, and represents a major step forward. But how do you reinvent the cable of tomorrow ?

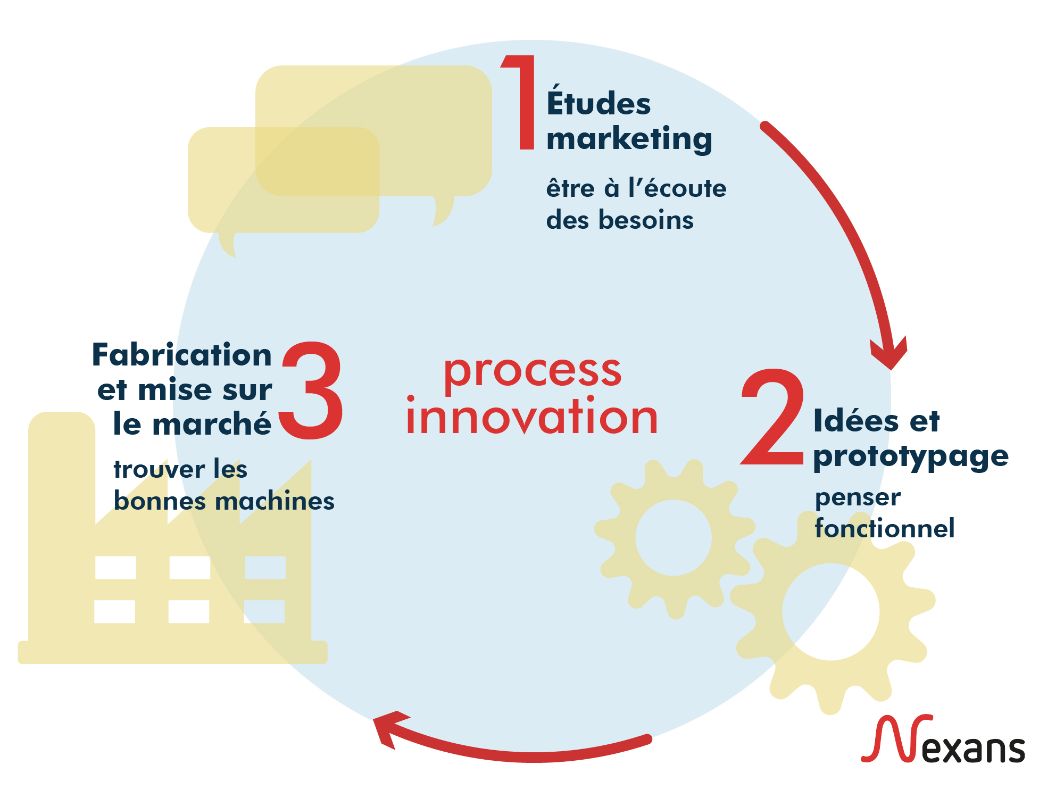

Innovation process

At Nexans, innovation is essential. It requires a great deal of human and financial investment to come up with the most relevant idea possible. The process from A to Z can take between 2 and 3 years, depending on the complexity of the product. One of the key steps to innovation is listening to you. You, the electricians, are involved at every stage of the innovation process: the new product designed will aim to make your daily life easier.

As such, the product must be adapted to your needs.

Marketing research

Marketing research is the starting point of the innovation process: it's a crucial stage in determining the need. The first step is to determine the target audience, i.e. the people for whom the future product will be aimed.

The second stage involves carrying out market research, in the form of questionnaires or discussions for example. The aim will be to find out more about the "pain points" in your daily life as an electrician.

These studies will then lead to ergonomic or anthropological studies carried out by specialist companies, in order to observe your day-to-day practices. Finally, the results of these various studies will be compiled in a brief, which will present all the elements found and a list of issues to be resolved. This study stage can take between a few weeks and a few months.

Finding solutions and designing prototypes

Once the issues have been determined, the second stage will be to hold design thinking and ideation workshops with designers. Thanks to the brief drawn up earlier, the designers will be able to come up with ideas and concepts to solve the problems.

The ideas are then sorted to select the most interesting ones. An initial conception of the solutions is drawn up and submitted to electricians during a focus group discussion. This discussion, which serves to gather the target group's initial impressions, will lead to a selection by the electricians with a validation of the problem addressed, to ensure that the idea is in line with the need.

The validated idea will be developed into an MVP (Minimum Viable Product). This product will then be re-submitted to electricians via an acceptability study, to gather data on whether the people questioned would be prepared to adopt the innovation, recommend it to others, and at what price they would buy it. Depending on the results obtained, the product will then be reworked until a satisfactory level of acceptability is achieved, which will be represented by a minimum of 80% of respondents being prepared to buy it. This prototyping stage takes a minimum of 6 months, but can vary depending on the number of iterations required to achieve the best result.

Opportunities for improvement

Although cables are functional products whose purpose is to conduct electricity, they are also consumer products, which you, as electricians, have to buy. Whatever your reasons for buying one cable rather than another, there are a number of significant advantages.

Learn more about this: